3D Printed Lathe Bar Puller HP Jet Fusion 3D 4210/4200 METAL X Rapid Prototyping Printing

CNC 3D Printed Lathe Bar Puller

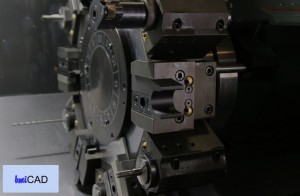

BMI CAD uses Markforged to print feed stock automation tools for a CNC lathe. Each puller is turret

mounted and uses friction to move heavy metal feedstock.

Effortlessly Customizable

Conventional CNC 3D Printed Lathe Bar Pullers are a workaround — they replace $10k-$30k automatic feeding systems with a turret mounted part. However, they’re still expensive and not designed specifically to stock specifications. By printing a unique bar puller for each type of stock, bmi CAD found a cost effective, stock specific solution that leverages Onyx’s surface and fiberglass’ strength to improve performance.

Affordable Metal 3D Printing

The Metal X is up to 10x less expensive than alternative metal additive manufacturing technologies — and up to a 100x less than traditional fabrication technologies like machining or casting.

Manufacturing Made Easy

Our cloud-based printer management software, built-in touchscreen interface and automatic material tracking make the Metal X system the simplest way to manufacture metal parts.https://www.youtube.com/watch?v=w0133NVRZJI&feature=emb_logohttps://www.youtube.com/watch?v=InYfu5hoV7c&feature=emb_logo

Atomic Diffusion Additive Manufacturing

At the intersection of 3D printing and metal injection molding, ADAM is an all new way to build metal parts.

DESIGN

CAD your part, upload the STL, and select from a wide range of metals. The Eiger software does the rest making printing the right part easy.

Metal powder bound in plastic is printed a layer at a time into the shape of your part. Parts are scaled up to compensate for shrinkage during the sintering process.

SINTER

Printed parts go through a washing stage to remove some of the binder. They are then sintered in a furnace and the metal powder fuses into solid metal.

PART

Pure metal and up to 99.7% dense, the final parts are ready for use. They can be processed and treated just like any other metal parts.