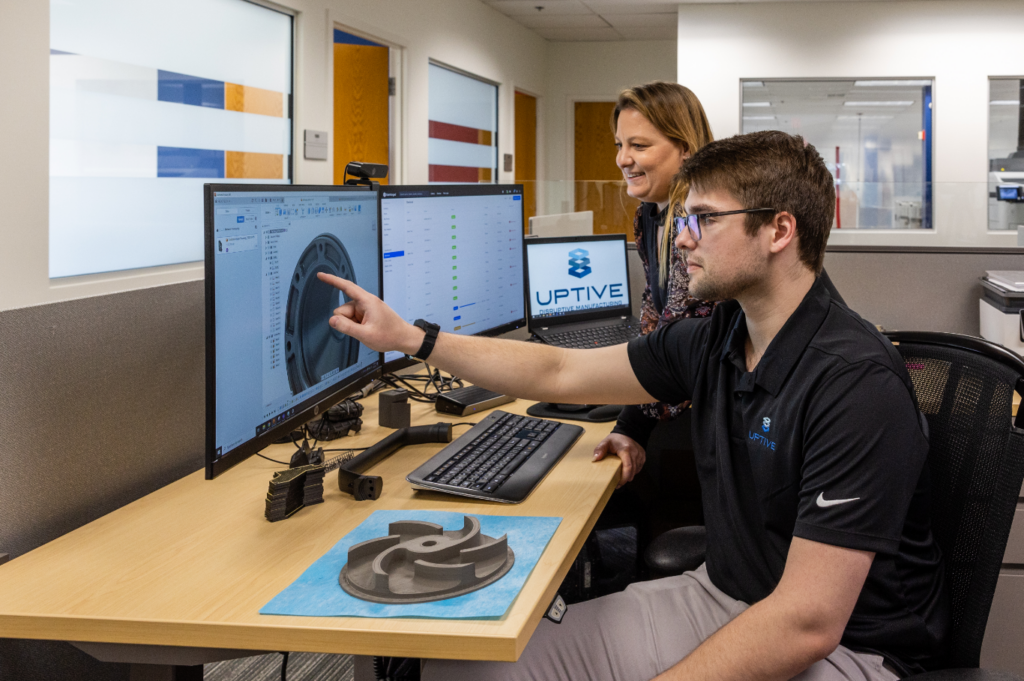

Customer-Centric Service, Cutting-Edge Technology

Welcome to UPTIVE. We’re creating a disruptive force in the rapid manufacturing industry by bringing the human touch back to the industry. From 3D printing services to traditional manufacturing, prototypes to large-scale production runs, we offer step-by-step advice and accurate, custom-part development to help bring your vision to life faster.

- Personalized service with a fast and easy quoting process

- Expert guidance to ensure manufacturability and scalability

- Collaborative, long-term partnerships focused on innovation

- Extensive Knowledge Base to educate and share the information you need

The UPTIVE Way

Let’s be real, technology, automation, and robotics have stripped away probably the most important piece in the product development process – personal service. At UPTIVE, technology is a tool that allows our team to recommend a wide range of options that factor in your specific needs for each stage of the part-production process.

Our Process

While other rapid manufacturing companies want to take your design file and generate an auto-quote, we work with you to ensure each part is designed for long-term manufacturability and production.

Our Partnership Doesn’t End There

We understand that each part is just one step in your digital manufacturing journey. We’ll continue to provide support to refine your materials and methods for better scalability and production forecasting.

What Drives Us to be Different

We believe our customers are the driving force behind innovation and we’re passionate about bringing your vision to life. With 5 locations spanning the US and Mexico, as well as multiple certified partners around the world, we can offer the expertise needed to help you through every part of the production process.

What We Do

We leverage both traditional and advanced additive manufacturing processes (3D printing services) to bring your ideas to life. This flexibility allows us to produce everything from prototypes to large-scale production runs, giving our customers the ability to scale their production as their needs change.

Why We Educate

Educating our customers is critical to empowering you to make informed decisions about your part-production needs. Our knowledge base is regularly updated with case studies, news, and other resources to educate you on all things digital manufacturing.

Why It Matters

For a customer, time is money, and any delays in product development can lead to missed opportunities, lost revenue, and a competitive disadvantage. By partnering with UPTIVE, you can leverage our expertise to optimize your part design and production processes to stay ahead of the competition.

How We Define “Disruptive”

In an industry full of automated quotes, limited personalization, and faceless transactions, we’re bucking the trend by going back to putting the customer first. This disruptive approach, or UPTIVE for short, ensures we understand “what” you’re looking for and “why,” before we even think about “how.” This allows us to provide the best guidance throughout the design and production process, giving us the flexibility to produce parts at any stage of development.

By putting you, the customer, first and providing personalized support every step of the way, we’re creating a disruptive movement in a field that prioritizes volume over customer service.